Coating Structure:

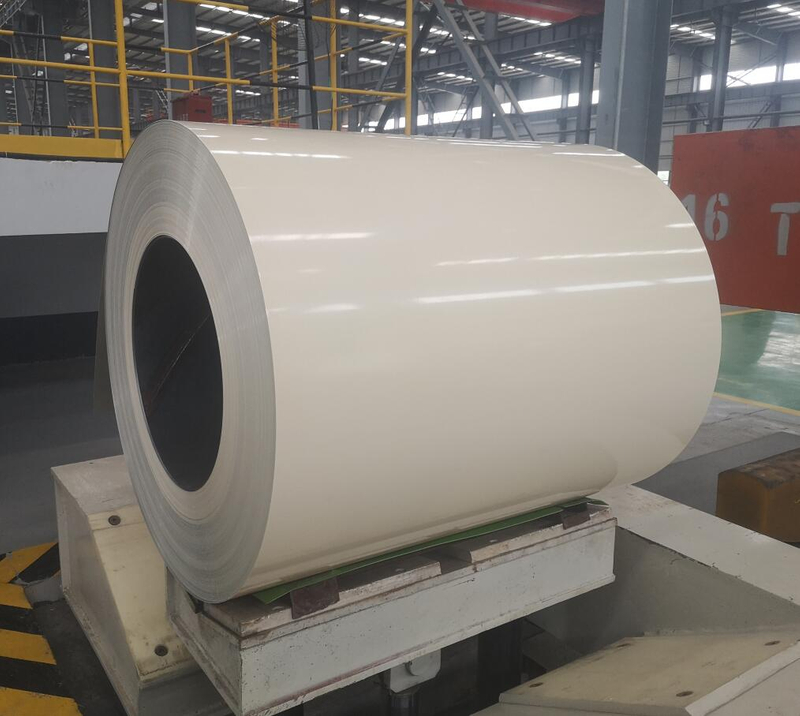

The Base Plate:

According to the use of powder color coated plate, structure forming, use environment and other factors to choose galvanized, galvalume and alu-zinc magnesium, cold plate, stainless steel, aluminum plate and other different substrates DX51D, DX52D, DX53D, S350GD, S550GD and other materials according to the customers’ requirements.

Product Advantage:

(1)Ultra-high Film Thickness and Ultra-high Density

The film thickness of traditional solvent coated plate is generally within 25 microns, while the film thickness of powder coated plate is more than 120 microns. The molecular weight of polymer powder coating is much higher than that of solvent coating. After curing at high temperature, ultra-dense coating is formed, which can effectively resist the invasion of corrosion factors and play a good role in protecting the substrate.

(2)Acid and Alkali Resistance, Gold Armor Protection

Polymer powder coating by high temperature curing, acid and alkaline resistance can be significantly improved, is the traditional solvent color coating 5-6 times, known as the building metal envelope" gold armor protection" .

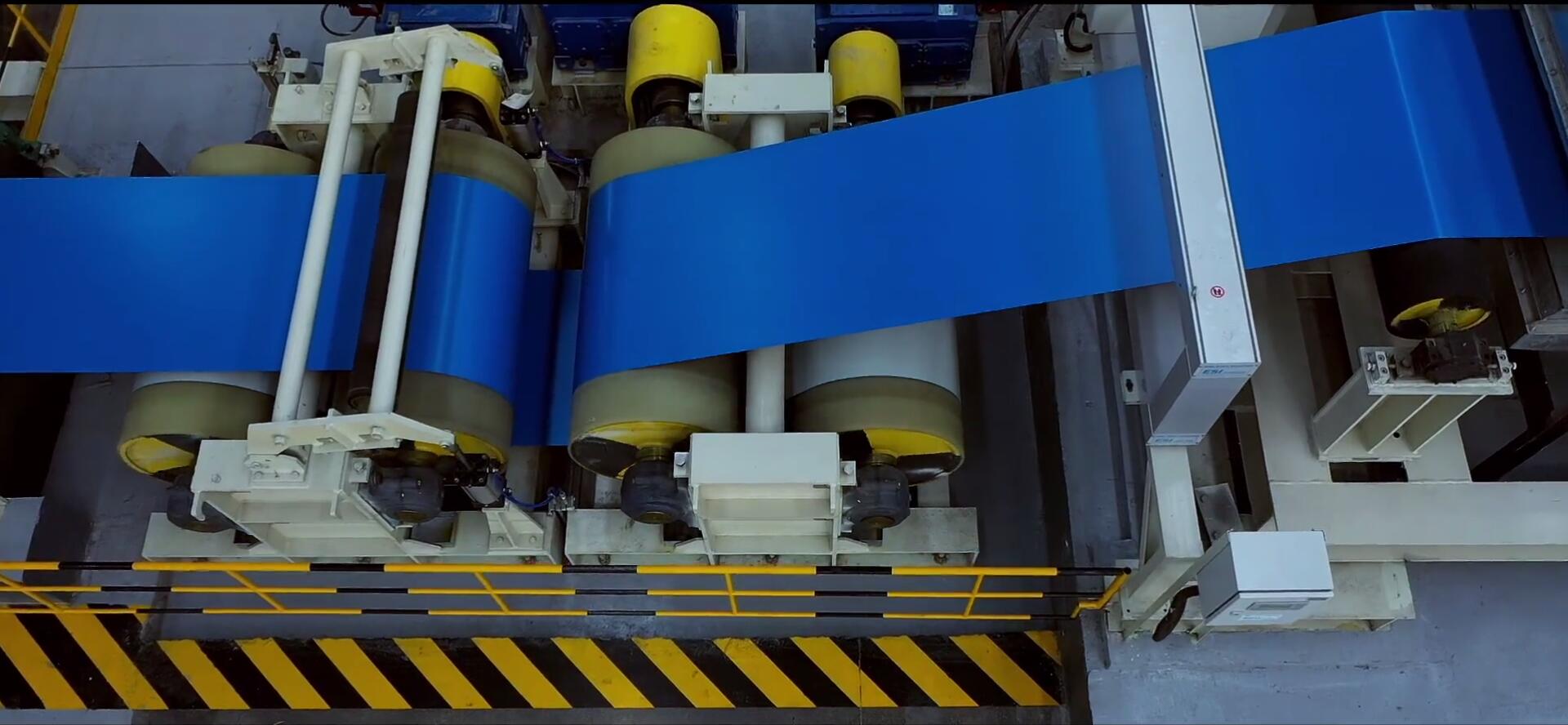

(3)Full Coating, Excellent Processing

High film thickness coating technology, plate surface looks more full, more delicate, 180° bending, coating does not crack, do not fall off, better processing performance, coating after high temperature curing hardness up to more than 5H.

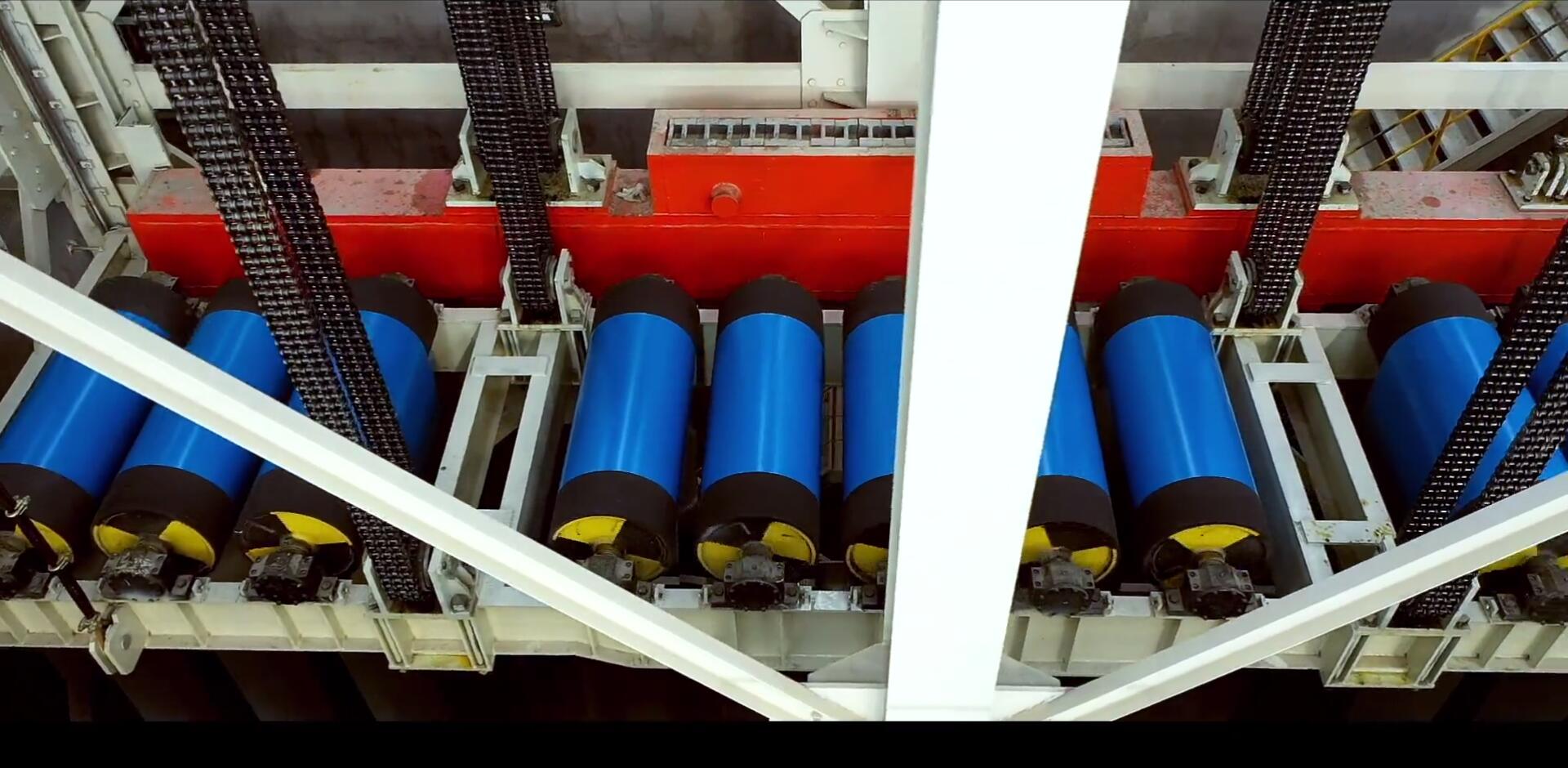

(4)VOC emission is zero and there is no pressure for environmental protection

Powder color coated board is made of high speed electrostatic spraying of polymer powder coating, with 100% solid content, no solvent volatilization, zero VOCs emission, effectively solved the environmental pressure such as air and water pollution.

(5)Energy Saving and Labor Saving

Due to the application of high speed electrostatic spraying technology, the powder coating plate can be cured quickly in 15-30 seconds, which greatly saves energy consumption and improves efficiency compared with the 15-30 minutes curing time of traditional spraying technology. At the same time, the pre-spraying splicing process replaces the traditional welding spray process, which greatly saves labor and improves the yield of finished products.

Perfect Quality Control System

Modern R & D Center

A modern powder color coating research and development center, focusing on the development and promotion of new technology of powder color coating products.

Strict Product Standards

Higher than the national standard "continuous pre-spraying powder color coating steel plate and steel belt" enterprise standards. Working with the relevant national departments, scientific research institutions, industry associations to jointly develop national standards for powder color coated plates to promote the upgrading of China's energy conservation and environmental protection color plate industry, .

Authoritative Third Party Testing

Products once through SGS and national building materials testing center authority testing certification, to meet the safety standards of most countries in the world, the export process can be smooth customs clearance.

Perfect Testing Process

In order to ensure the zero defects of each product out of the warehouse, established a sound product quality management process, to achieve the whole process of coating products control.

① Review raw material purchase requirements

Make sure the order demand and production capacity

② Review raw material purchase requirements

Make sure the order demand and inventory raw materials match

③ Cold-rolled on-line detection

Appearance, Strength, etc.

④ Galvanized on-line detection

Zinc Plate, Plate Type, Thickness, etc.

⑤ Galvanized Product Testing

Zinc Coating Weight, Adhesion and Strength, etc.

⑥ Galvanized Warehousing Detection

Appearance, Label

⑦ Painted material on-line detection

Such as Zinc, Zinc Adhesion Layer Weight

⑧ Product on-line detection

Plate type, board face, coating layer thickness, surface quality, etc.

⑨ Product performance testing

MEK solvent resistant to wipe, Coating Adhesion, Coating Thickness, Pencil Hardness, Strong Adhesion

⑩ Product put in storage test

Package, label

⑪ Product output and delivery test

Appearance, Label and Invoice match